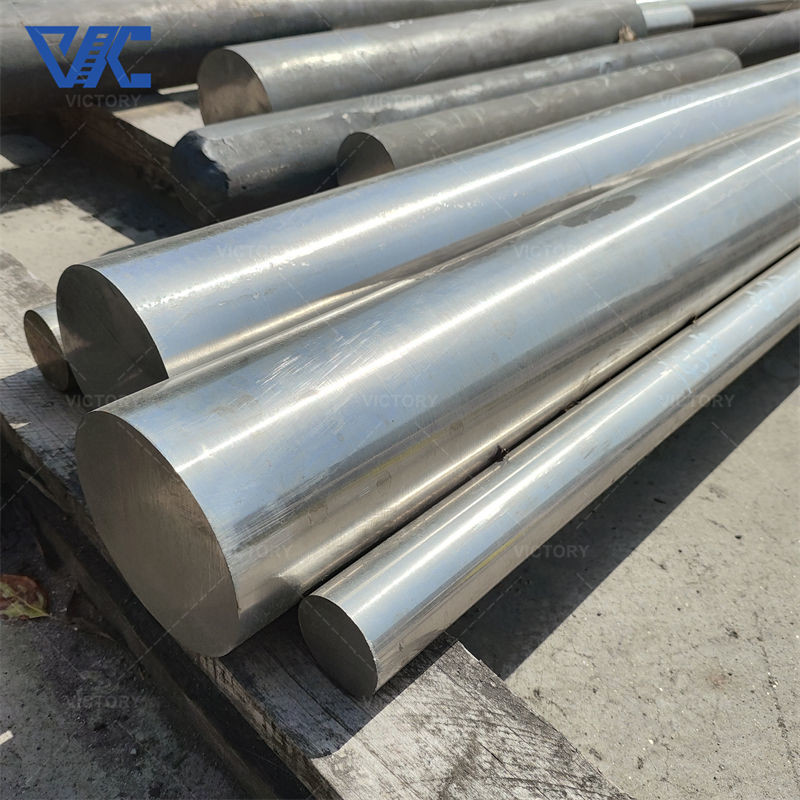

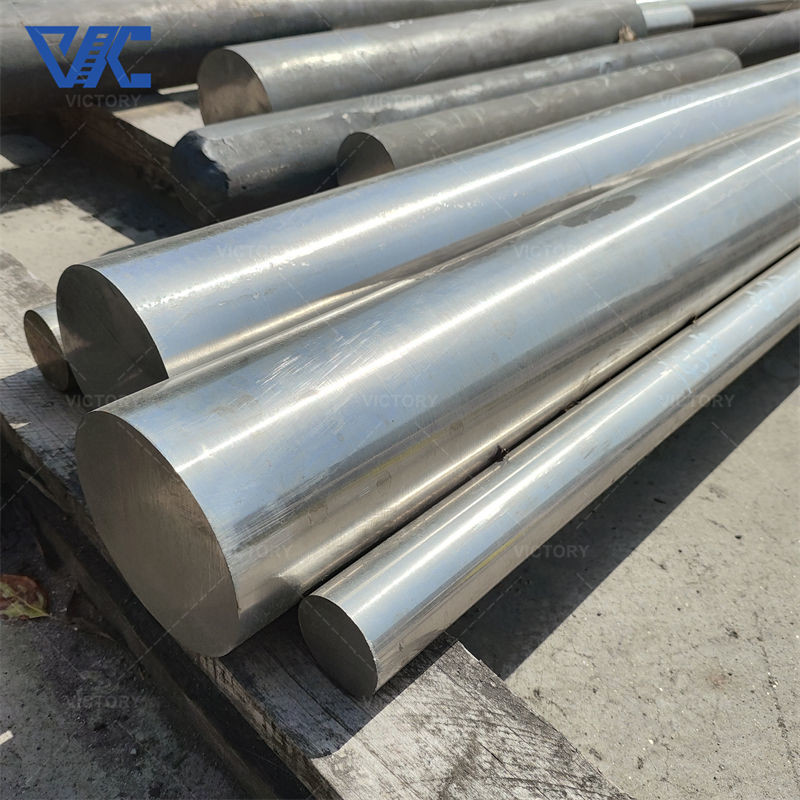

Inconel 718 alloy

INCONEL alloy 718 has excellent corrosion resistance to many media. This resistance, which is similar to that of other nickel-chromium alloys, is a function of its composition. Nickel contributes to corrosion resistance in many inorganic and organic, other than strongly oxidizing, compounds throughout wide ranges of acidity and alkalinity. It also is useful in combating chloride-ion stress-corrosion cracking.

The key mechanical properties and characteristics that make Inconel 718 a high-performance alloy

Inconel 718 is recognized as a high-performance alloy due to its exceptional mechanical properties and characteristics. Here are the key properties that contribute to its performance:

Key Mechanical Properties

High Yield Strength:

Retains high yield strength (up to 1,200 MPa or more) at both room and elevated temperatures, making it suitable for high-stress applications.

Tensile Strength:

Exhibits excellent tensile strength (up to 1,400 MPa) which is critical for components subjected to heavy loads.

Fatigue Resistance:

Outstanding resistance to fatigue failure, allowing it to withstand cyclic loading without significant degradation over time.

Ductility:

Good ductility ensures that the material can deform without fracturing, which is essential for applications that require resilience under stress.

Impact Toughness:

Maintains toughness even at low temperatures, making it suitable for applications where impact resistance is critical.

Creep Resistance:

Excellent resistance to creep deformation at elevated temperatures, which is crucial for components operating in high-temperature environments.

Parameter:

Chemical Properties of Inconel 718

Nickel (plus Cobalt) .......................................................50.00-55.00

Chromium......................................................................17.00-21.00

Iron .....................................................................................Balance

Niobium (plus Tantalum)....................................................4.75-5.50

Molybdenum .....................................................................2.80-3.30

Titanium.............................................................................0.65-1.15

Aluminum ..........................................................................0.20-0.80

Cobalt ...............................................................................1.00 max.

Carbon..............................................................................0.08 max.

Manganese .......................................................................0.35 max.

Silicon ...............................................................................0.35 max.

Phosphorus.....................................................................0.015 max.

Sulfur...............................................................................0.015 max.

Boron ..............................................................................0.006 max.

Copper..............................................................................0.30 max

| Density | 8.19g/cm³ | 0.296 lb/in³ |

| Melting point | 1260-1336 | 2437°F |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

Billet and bar for reforging | |

| | |

Inconel series

| Steel grade | Inconel 600 | Inconel 601 | Inconel 625 | Inconel 718 | Inconel 725 | Inconel X-750 |

| Corresponding brand | N06600/2.4816/1Cr15Ni75Fe8/NS312/CY40 | N06601/2.4851/1Cr23Ni60Fe13AI/NS313 | N06625/2.4856/0Cr20Ni65Mo10bN4/NS336 | N07718/2.4668/GH4169 | N07725 | N07750/2.4669/GH4145 |

| Chemical composition% |

| C≤ | 0.150 | 0.100 | 0.100 | 0.080 | 0.030 | 0.080 |

| Mn≤ | 1.00 | 1.00 | 0.50 | 0.35 | 0.35 | 1.00 |

| P≤ | / | / | 0.015 | 0.015 | 0.015 | / |

| S≤ | 0.015 | 0.015 | 0.015 | 0.015 | 0.010 | 0.010 |

| Si≤ | 0.50 | 0.50 | 0.50 | 0.35 | 0.20 | 0.50 |

| Cr≤ | 14.0-17.0 | 21.0-25.0 | 20.0-23.0 | 17.0-21.0 | 19.0-22.5 | 14.0-17.0 |

| Ni≤ | ≥72.0 | 58.0-63.0 | ≥58.0 | 55.0-59.0 | 55.0-59.0 | ≥70 |

| Mo | / | / | 8.0-10.0 | 2.8-3.3 | 7.0-9.5 | / |

| Cu | ≤0.50 | ≤1.50 | / | ≤0.30 | / | ≤0.50 |

| N | / | / | / | | / | / |

| Nb | / | / | 3.15-4.15 | 4.75-5.50 | 2.75-4.00 | 0.70-1.20 |

| other | Fe:6.0-10.0 | Al:1.0-1.7 | Co:≤1.0Ai:≤0.40Tr:0.40Fe:≤5.0 | AI:0.20-0.80Ti:0.65-1.15B≤0.006 | Tr:1.0-1.7AI≤0.35 | Co:≤1.0 AI:0.4-1.0Tr:0.25-2.75Fe:5.0-9.0 |

Customize size as below

| Shape | Size(mm) |

| WIre | 0.5-7.5 |

| Rod/Bar | 8.0-200 |

| Strip | (0.5-2.5)*(5-180) |

| Tube | custom made |

| Plate | custom made |

contact us

email:victory@dlx-alloy.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service