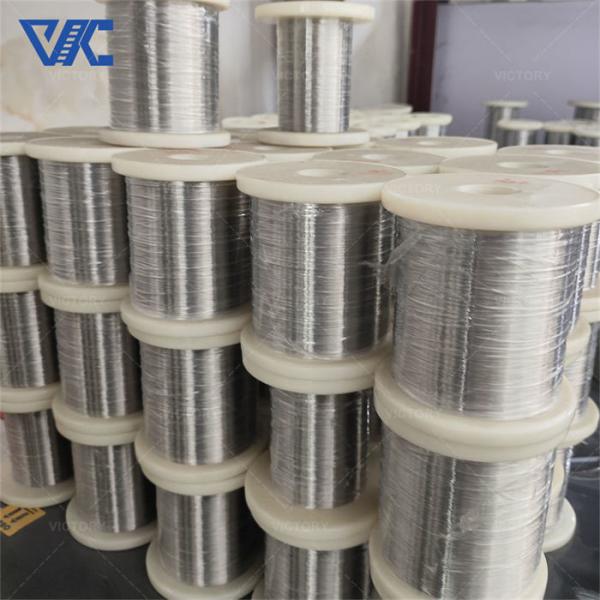

FeCrAl Alloy 0Cr23Al5 D Electric Resistance Round Wire For Industry

Oven Heating Elements

General Introduction:

0Cr23Al5 wire is a type of electrical resistance wire that belongs

to the family of iron-chromium-aluminum (FeCrAl) alloys. The

designation "0Cr23Al5" indicates the composition of the alloy, with

0% nickel, 23% chromium, and 5% aluminum. This alloy is known for

its high electrical resistance, good oxidation resistance at

elevated temperatures, and excellent mechanical properties.

0Cr23Al5 wire is commonly used in heating elements for applications

requiring high temperatures, such as in electric furnaces, ovens,

kilns, and industrial heating processes. It can withstand

temperatures up to 1250°C (2282°F) and offers stable performance

over a wide temperature range due to its low temperature

coefficient of resistance.

Main Features:

1. High Electrical Resistance: 0Cr23Al5 wire exhibits high

electrical resistance, making it suitable for heating applications

where controlled heat generation is required.

2. Good Oxidation Resistance: This wire has good oxidation

resistance at high temperatures, ensuring longevity and performance

in demanding environments.

3. High Temperature Capability: 0Cr23Al5 wire can withstand high

temperatures up to 1250°C (2282°F), making it ideal for

applications requiring heat resistance.

4. Low Temperature Coefficient of Resistance: It has a low

temperature coefficient of resistance, providing stable performance

over a wide temperature range.

5. Excellent Mechanical Properties: The wire possesses good

mechanical properties, contributing to its durability and

reliability in industrial applications.

6. Corrosion Resistance: It offers good corrosion resistance,

making it suitable for use in various environments.

7. Versatile Applications: 0Cr23Al5 wire is used in a variety of

applications such as electric furnaces, ovens, kilns, and

industrial heating processes due to its balanced properties.

How does the FeCrAl wire works in industry furnace system?

FeCrAl wire works in industrial furnace systems by serving as the

heating element that generates heat through electrical resistance.

When an electric current passes through the FeCrAl wire, its high

electrical resistance causes the wire to heat up. This heat is then

transferred to the surrounding environment, allowing the industrial

furnace system to reach and maintain high temperatures required for

various processes.

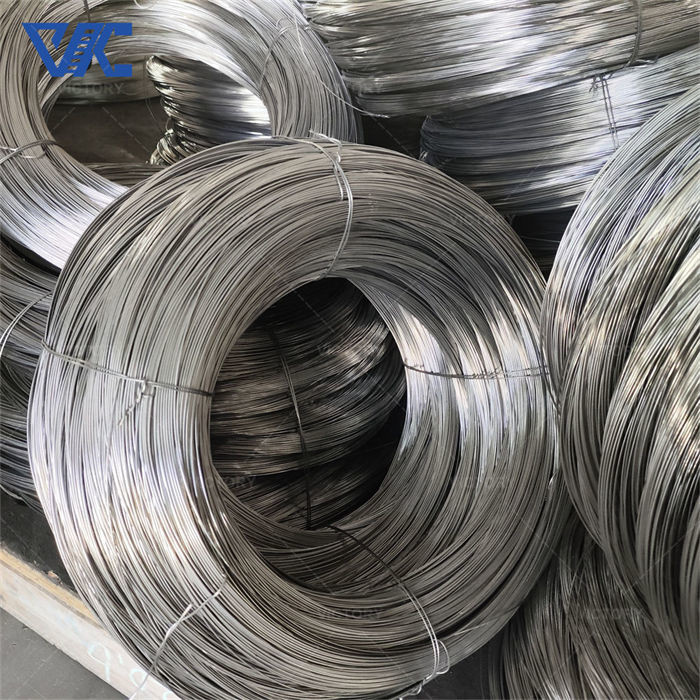

In an industrial furnace system, FeCrAl wire is typically wound

into coils or placed in a specific configuration to maximize heat

generation and distribution. The wire's high oxidation resistance

ensures that it can withstand the high temperatures and harsh

conditions inside the furnace without degrading quickly.

By controlling the electrical current passing through the FeCrAl

wire, the temperature within the furnace system can be regulated

and maintained at the desired level for specific industrial

processes such as heat treatment, metal melting, glass production,

and more.

Overall, FeCrAl wire plays a crucial role in industrial furnace

systems by providing reliable and efficient heating elements that

can operate at high temperatures consistently, contributing to the

overall performance and productivity of industrial processes.

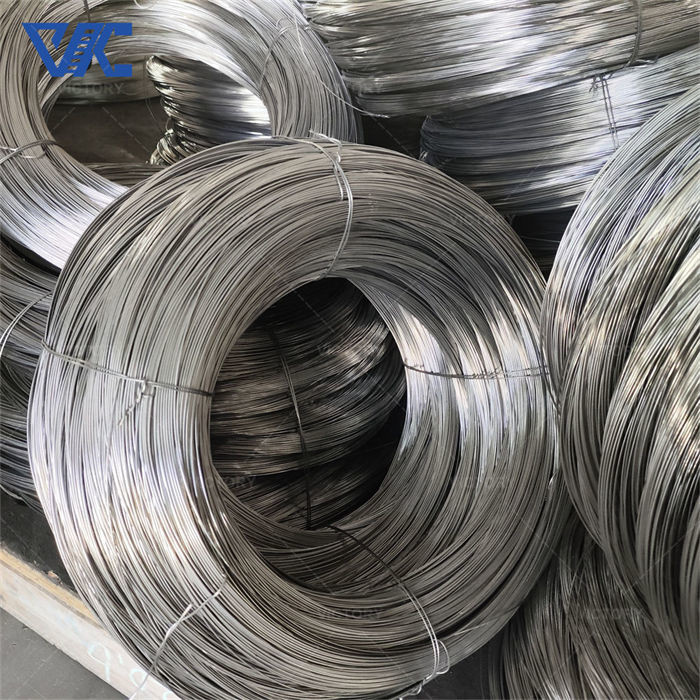

| Shape | Size (mm) |

| Wire | 0.025-8.00mm |

| Rod | 8.00-50.00mm |

| Robbin | (0.05-0.35)*(0.5-6.0)mm |

| Strip | (0.50-2.50)*(5.00-180.00)mm |

| Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4/ 0Cr19Al3 | 0Cr21Al6Nb | 0Cr27Al7Mo2 |

| Main chemical composition | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 |

| Rest | opportune | opportune | opportune | opportune | opportune | opportune | opportune |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest |

| Others | -- | -- | -- | -- | -- | Nb 0.5 | Mo 1.8-2.2 |

| Max. continuous service temp. of element( °C ) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 |

| Resistivity at 20ºC(μΩ@m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 |

| Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 |

| Thermal conductivity(KJ/m@h@ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | |

| Line expansion coefficient(α×10-6/ºC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 |

| Melting point approx.( ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 |

| Tensile Strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 |

| Elongation at break(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 |

| Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 |

| Repeat bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 |

| Hardness (H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 |

| continuous service time(Hours/ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 |

| Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite |

| Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic |

Are you a Manufacturer or Trader?

We are a Manufacturer.

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all

the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal.

What is the lead time?

Usually sample lead time is 7 days after payment has been

confirmed.