Is Inconel stronger than stainless steel?

in general, Inconel alloys tend to be stronger than stainless steel

alloys.

Tensile Strength:

Inconel alloys like Inconel 600 and Inconel 718 have higher

ultimate tensile strengths compared to common stainless steel

grades like 304 or 316.

For example, Inconel 718 can have an ultimate tensile strength of

around 1,500 MPa, while 304 stainless steel is around 505 MPa.

Yield Strength:

Inconel alloys also exhibit higher yield strengths than many

stainless steels.

Inconel 718 has a yield strength of around 1,035 MPa, while 304

stainless steel is around 215 MPa.

High Temperature Strength:

Inconel alloys maintain their strength better than stainless steels

at elevated temperatures, making them suitable for high-temperature

applications.

Corrosion Resistance:

While stainless steels have good corrosion resistance, Inconel

alloys can offer even better resistance to corrosion in harsh

environments.

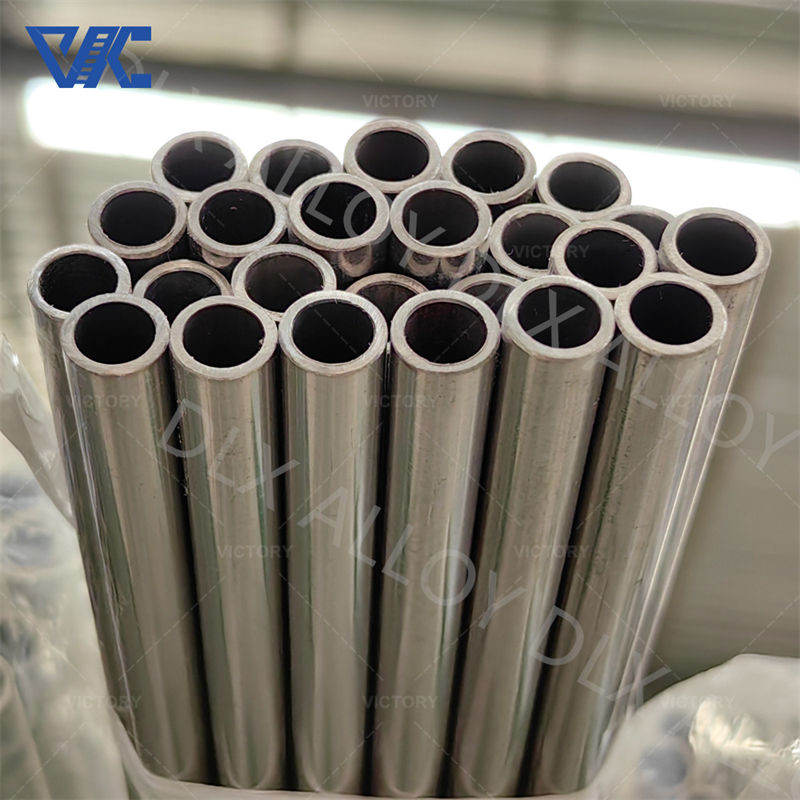

The production process of inconel 600 tube

Melting and Casting:

Inconel 600 is produced by melting the raw materials, which include

nickel, chromium, iron, and small amounts of other alloying

elements.

The molten metal is then cast into ingots or billets.

Hot Working:

The cast ingots or billets are heated to high temperatures

(typically around 1100-1200°C) and then subjected to hot forming

processes, such as hot rolling or hot extrusion.

This hot working step reduces the cross-sectional area and

increases the length of the material, creating a solid, seamless

tube shell.

Cold Working:

The hot-worked tube shell is further processed through cold working

techniques, such as cold drawing or cold pilger rolling.

This cold working step helps to further reduce the tube's diameter

and wall thickness, while also improving the mechanical properties

of the material.

Heat Treatment:

After the cold working, the Inconel 600 tube undergoes a specific

heat treatment process, which typically involves solution

annealing.

The solution annealing helps to homogenize the microstructure,

relieve internal stresses, and enhance the corrosion resistance of

the Inconel 600 tubing.

Inspection and Quality Control:

The final Inconel 600 tubes are inspected for dimensional accuracy,

surface quality, and adherence to material specifications.

Various non-destructive testing techniques, such as ultrasonic

testing or eddy current testing, may be employed to ensure the

integrity of the tubing.

Surface Finishing:

Depending on the application, the Inconel 600 tubes may undergo

additional surface finishing processes, such as pickling,

passivation, or electropolishing, to further enhance their

corrosion resistance and appearance.