Dimension:

Size dimension range:

Wire: 0.01-10mm

Ribbons: 0.05*0.2-2.0*6.0mm

Strip: 0.05*5.0-5.0*250mm

Bar:10-50mm

Nickel 200 nickel wire 0.025 mm dia

It has good mechanical strength,corrosion-resistant and

heat-resistance strength.

It is widely used in electric apparatus,chemical machinery,ood

processing equipment,rechargeable batteriesomputers, cellular

Phone, power tools, camcorders and so on.

Features:

1. Low resistance, make the battery pack more powerful, save

energy.

2. Pure Nickel to make it easy welding, stable connection

3. Dood tensile and easy operate assembly.

4. shaped design, save too much work for customer to assembly

battery pack.

5. High Electrical Conductivity

6. Anti-corrosive and low resistance

Physical properties:

1.Spot welding is good

2.The resistance is lower

3. Battery discharge time longer

4. The battery spot welding is stronger.

Functions/Applications:

1. manufacturing nickel-cadmium battery

2. nickel-hydrogen battery

3. lithium cell

4. assembled battery

5. industries of electric tool and special lights

6. Superconductor Applications

Specification

| Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

| N4 | 99.8 | 0.015 | 0.03 | 0.002 | 0.01 | 0.01 | 0.001 | 0.001 | 0.04 |

| N6 | 99.6 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

| Ni201 | ≥99.0 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

| Ni200 | ≥99.2 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

| Physical Data | |

| Density | 8.89g/cm3 |

| Specific Heat | 0.109(456 J/kg.ºC) |

| Electrical Resistivity | 0.096×10-6ohm.m |

| Melting Point | 1435-1446ºC |

| Thermal Conductivity | 70.2 W/m-K |

| Mean Coeff Thermal Expansion | 13.3×10-6m/m.ºC |

| |

| Typical Mechanical Properties | |

| Mechanical Properties | Nickel 200 |

| Tensile Strength | 462 Mpa |

| Yield Strength | 148 Mpa |

| Elongation | 47% |

| Our Production Standard | | | | |

| Bar | Forging | Pipe | Sheet/Strip | Wire |

| ASTM | ASTM B160 | ASTM B564 | ASTM B161/B163/B725/B751 | AMS B162 | ASTM B166 |

Pure nickel wire finds widespread applications in various fields.

Here are some common areas of application:

1. Resistance heaters: Pure nickel wire possesses excellent

resistance properties and is extensively used in the manufacturing

of resistance heaters and heating elements, such as air furnaces,

heating coils, and heaters.

2. Electronic components: Pure nickel wire is widely used in the

field of electronic components, including resistors, inductors, and

electronic circuitry interconnects.

3. Chemical industry: Due to its corrosion resistance and

high-temperature performance, pure nickel wire is applied in the

chemical industry for corrosion-resistant equipment, reactors,

pipelines, and other components.

4. Petroleum and petrochemical industry: Pure nickel wire is

utilized in the manufacturing of corrosion-resistant equipment and

pipelines for the petroleum and petrochemical industry, including

petrochemical plants, pipeline connections, and storage tanks.

5. Aerospace industry: Pure nickel wire finds extensive use in the

aerospace field for manufacturing high-temperature and

high-strength components such as engine parts, combustion chambers,

nozzles, and turbine blades.

6. Other industries: Pure nickel wire also finds applications in

the power industry, electronics and electrical engineering, and

nuclear energy industry, used for manufacturing cables,

electromagnetic coils, and electric heating devices.

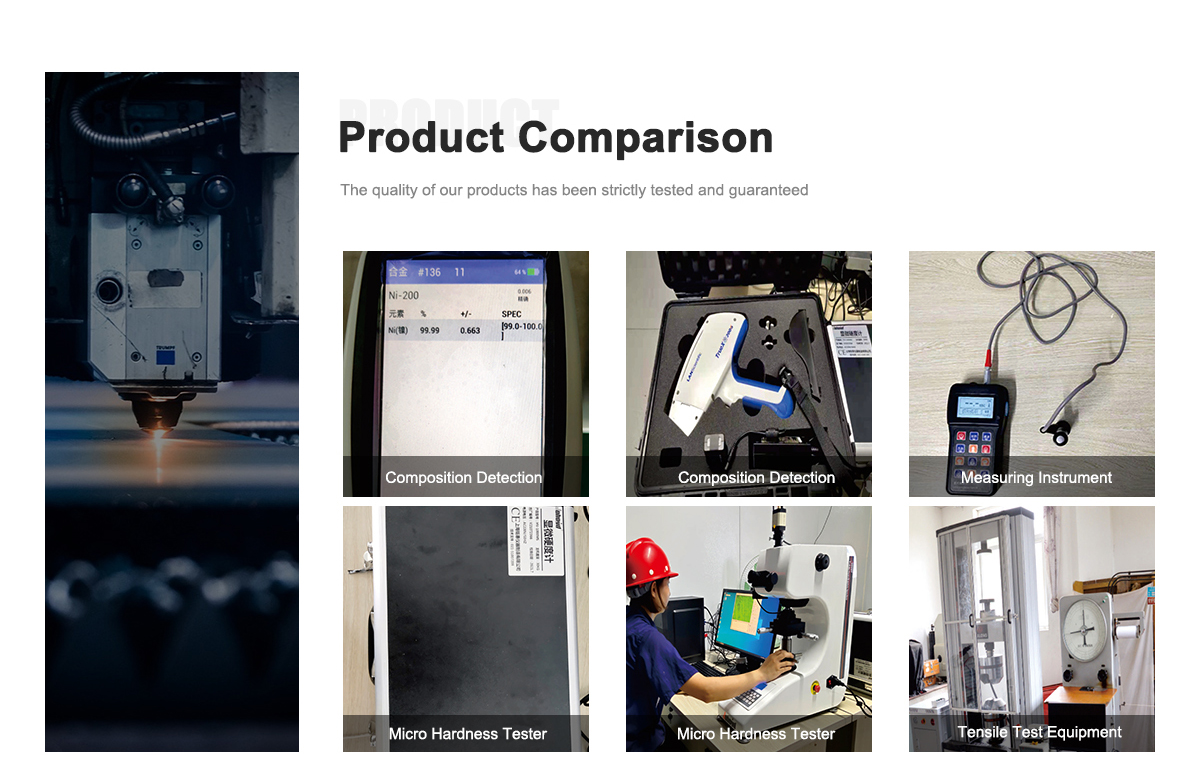

OEM Services

We offer personalized customization services for both products and

labels to meet the specific needs of our customers. We can provide

products with different thicknesses and widths according to the

customer's requirements. Whatever kind of customization service our

customers need, we will do our best to meet their demands and

ensure customer satisfaction.