Introduction:

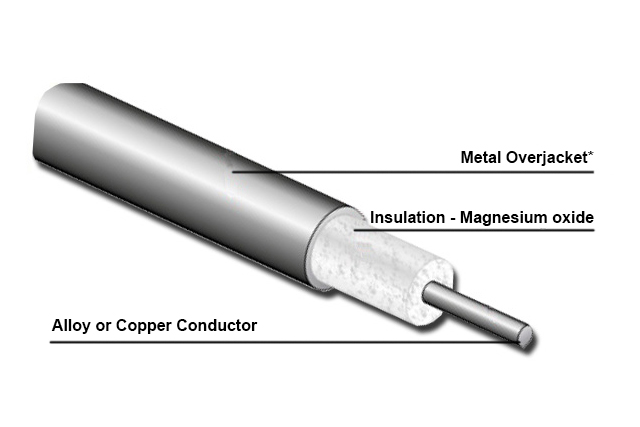

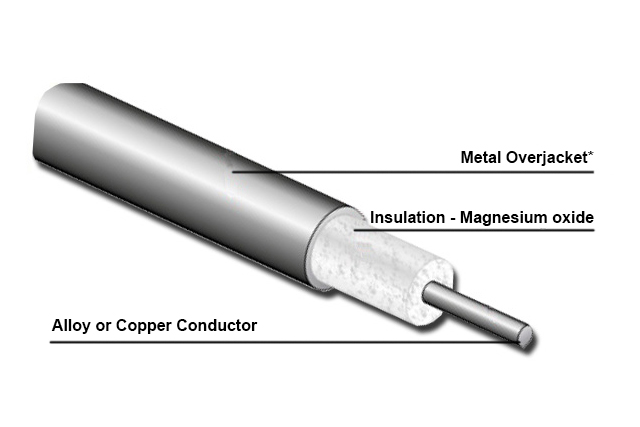

Armored thermocouples are a commonly used tool when it comes to

temperature measurement and control during metal processing and

heat treatment. They are composed of two different metal wires that

are wrapped in a protective sleeve to form a sturdy sensor.

Armored thermocouples work based on the thermoelectric effect,

which means that when two wires of a thermocouple are connected in

metals of different temperatures, a voltage is produced. There is a

definite relationship between this voltage and temperature, so the

temperature value can be inferred by measuring the voltage.

This type of thermocouple is very useful in the metal processing

and heat treatment fields because of their ability to withstand

high temperature environments. Whether it is high temperature

annealing, melting, quenching or other heat treatment processes,

armored thermocouples provide accurate temperature measurements. In

addition, they have high response speed and good measurement

accuracy, which is very important for applications that require

fast response and precise temperature control.

When selecting an armored thermocouple, there are some key factors

to consider based on your specific requirements. For example,

temperature range is an important consideration because different

types of thermocouples are suitable for different temperature

ranges. In addition, the material of the protective sleeve is also

important, as it needs to be able to withstand high temperatures

and chemical attack. Other factors include thermocouple length,

diameter, and connector type, which will be selected based on the

specific application and installation needs.

All in all, armored thermocouples are reliable,

high-temperature-resistant temperature measurement and control

tools that are widely used in metal processing and heat treatment

processes. By measuring the thermoelectric effect, they provide

accurate temperature data to help ensure the quality and stability

of metal processing processes.

Product Features:

- High temperature measurement range: Armored thermocouples are

suitable for high temperature environments and can measure and

control high temperatures in metal processing and heat treatment

processes, usually ranging from hundreds to thousands of degrees

Celsius.

- Fast response: Armored thermocouples have fast response

capabilities to temperature changes, and can quickly sense

temperature changes and output corresponding electrical signals.

- Corrosion resistance: Armored thermocouples are made of high

temperature and corrosion resistant materials and can be used for a

long time in harsh environments during metal processing and heat

treatment.

Advantage:

- High temperature measurement accuracy: Armored thermocouples have

high measurement accuracy and stability and can provide accurate

temperature measurement results.

- Strong durability: The shell of the armored thermocouple is made of

materials such as metal or ceramic, which has good mechanical

strength and durability and can maintain stable performance in

long-term use.

- Real-time: Armored thermocouples can provide temperature data in

real time to meet the needs for real-time monitoring and control

during metal processing and heat treatment.

Specific applications:

- Smelting and casting: During the metal smelting and casting

process, armored thermocouples can be used to measure and control

the temperature inside the furnace to ensure that the smelting and

casting process is carried out within a suitable temperature range

to improve production quality and product performance.

- Annealing and quenching: During metal processing, armored

thermocouples can be used to measure and control the temperature

during annealing and quenching to ensure that the metal material

obtains the required structure and properties.

- Welding and heat treatment: During metal welding and heat

treatment, armored thermocouples can be used to monitor and control

the temperature of the welding area and heat treatment area to

ensure the quality and stability of the welding and heat treatment

process.

Other relevant knowledge:

Armored thermocouples usually consist of two different metal wires,

which generate a thermoelectric potential difference based on the

thermoelectric effect, and determine the temperature by measuring

the thermoelectric potential difference.

The selection of armored thermocouples should be based on specific

working conditions and temperature ranges. Different armoring

materials are suitable for different working environments and

temperature requirements.

Parameter:

Code | Wire Component of the thermocouple |

+Positive leg | - Negative Leg |

N | Ni-Cr-Si(NP) | Ni-Si-magnesium (NN) |

K | Ni-Cr(KP) | Ni-Al(Si) (KN) |

E | Ni-Cr(EP) | Cu-Ni (EN) |

J | Iron (JP) | Cu-Ni (JN) |

T | Copper (TP) | Cu-Ni (TN) |

B | Platinum Rhodium-30% | Platinum Rhodium -6% |

R | Platinum Rhodium-13% | Platinum |

S | Platinum Rhodium -10% | Platinum |

Material | Type | Grade | Working temperature (deg) | Tolerance | Standard |

Long Term | Short Term |

NiCr-NiSi | K | 1 | -40~1100 | -40~1300 | ±1.5 deg | GB/T 2614-1998 |

2 | ±2.5 deg |

NiCr-CuNi | E | 1 | -40~800 | -40~900 | ±1.5 deg | GB/T 4993-1998 |

2 | ±2.5 deg |

Fe-Constantan | J | 1 | -40~600 | -40~800 | ±1.5 deg | GB/T 4994-1998 |

2 | ±2.5 deg |

Cu-CuNi | T | 1 | -200~300 | -200~400 | ±0.5 deg | GB/T 2903-1998 |

Outer Sheath(mm) | core wire Dia.( mm) | Outer Sheath(mm)o core wire Dia.( mm) | Length(m) |

Out Dia | Wall Thickness | K,N,E,J,T Types | S,R,B Types | K,N Types | E,J,T Types | S,R Types | |

0.5 | 0.05-0.10 | 0.08-0.12 | ... | | | | | 500 |

1.0 | 0.10-0.20 | 0.15-0.20 | ... | 300 |

1.5 | 0.15-0.25 | 0.23-0.30 | ... | 200 |

1.6 | 0.16-0.26 | 0.26-0.36 | ... | 200 |

2.0 | 0.25-0.35 | 0.40-0.50 | 0.25-.030 | 180 |

3.0 | 0.38-0.48 | 0.50-0.60 | 0.30-0.40 | 80 |

3.2 | 0.48-0.58 | 0.58-0.68 | 0.30-0.40 | 75 |

4.0 | 0.52-0.62 | 0.60-0.70 | 0.35-0.40 | 70 |

4.8 | 0.73-0.83 | 0.75-0.85 | 0.40-0.45 | 40 |

5.0 | 0.78-0.88 | 0.80-0.90 | 0.40-0.45 | 40 |

6.0 | 0.98-1.08 | 0.90-1.10 | 0.45-0.50 | 30 |

6.4 | 1..05-1.15 | 1.02-1.12 | 0.45-0.50 | 30 |

8.0 | 1.30-1.44 | 1.30-1.40 | 0.45-0.50 | 20 |

12.7 | 1.75-1.90 | 1.95-2.05 | ... | 10 |

| Tolerance | | |

Special Limits (Grade I) | Standard Limits (Grade II) | Temperature Range (℃) |

K (Chromel vs Alumel) | | | -40~1000 |

J (Iron vs Constantan) | -40~750 |

E (Chromel vs Constantan) | -40~800 |

T (Copper vs Constantan) | ±1°C or ±0.75% | -40~350 |