Introduction:

0Cr21Al6Nb furnace wire is a high-temperature alloy material

commonly used in electric furnace heating elements, thermocouples

and resistance wires. The alloy is known for its excellent

oxidation resistance and high temperature resistance.

The chemical composition of 0Cr21Al6Nb furnace wire mainly includes

chromium (Cr), aluminum (Al) and niobium (Nb). Among them, the

content of chromium accounts for about 21% by mass, the content of

aluminum accounts for about 6% by mass, and the content of niobium

is relatively small, usually 0.5-1.5% by mass. The reasonable ratio

of these elements gives the furnace wire excellent high temperature

resistance.

The alloy has a high melting point (about 1500 degrees Celsius) and

can operate stably for a long time in high temperature

environments. It has excellent antioxidant capacity and can resist

oxidation, corrosion and deformation at high temperatures,

extending its service life. In addition, 0Cr21Al6Nb furnace wire

also has a low linear expansion coefficient, allowing it to

maintain good stability during thermal cycles.

The furnace wire has a high thermal conductivity, which helps to

conduct heat quickly and improve heating efficiency. At the same

time, it also has high tensile strength and yield strength, and can

withstand mechanical stress in high temperature environments. In

addition, 0Cr21Al6Nb furnace wire has a certain elongation at room

temperature, making it more flexible and easier to operate during

processing and installation.

Parameter:

Chromium (Cr): approximately 21% by mass

Aluminum (Al): approximately 6% by mass

Niobium (Nb): relatively small content, usually 0.5-1.5% mass ratio

Other elements: mainly iron (Fe) and impurity elements, such as

manganese (Mn), silicon (Si), etc.

Density: approximately 7.10g/cm3

Melting point: approximately 1500 degrees Celsius

Thermal Conductivity: Approximately 13-15 Watts/meter Kelvin

(around room temperature)

Linear expansion coefficient: approximately 13×10^-6/degrees

Celsius (within room temperature range)

Tensile strength: about 600-800 MPa

Yield strength: about 280-450 MPa

Elongation: approximately 10-25% (at room temperature)

item | value |

Place of Origin | Jiangsu,China |

Type | Fe-Cr-Aluminum Ribbon |

Application | Industry Furnace |

Conductor Material | ferro alloy |

Certificate | ISO9001 |

Thermal conductivity: | 15 W/(m.K) (20ºC) |

Executive standard | GB/T1234-2012 |

Dimensions | User's Demand |

Size | 0.56-5mm |

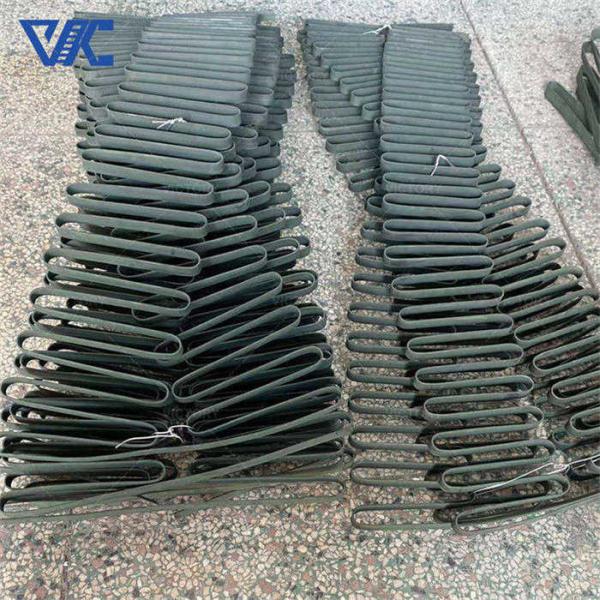

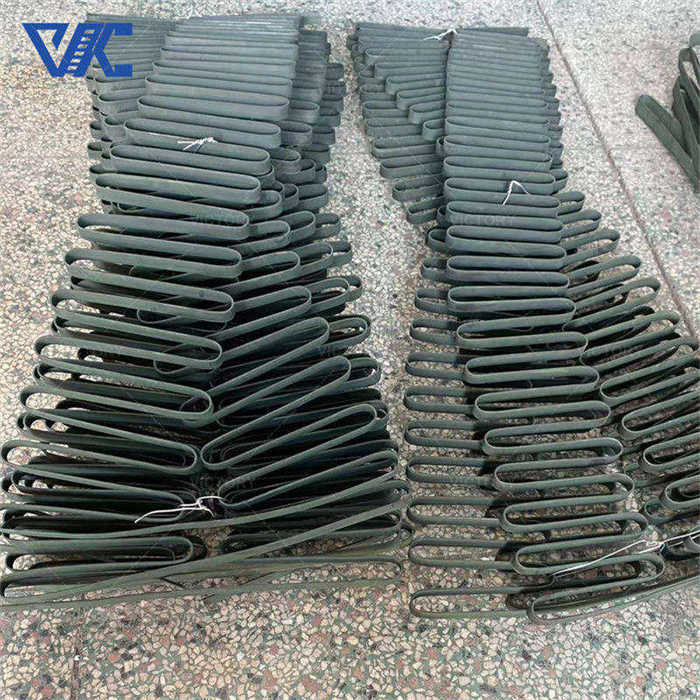

shape | shaped strip |

width | 6-50mm |

Packing | Pallet |

highest temperature | 1400ºC |

melting point | 1520ºC |

Alloy Nomenclature Performance | 1Cr13AL4 | 0Cr25Al5 | 0Cr21AL6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 |

Main Chemical composition

| Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 |

Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest |

| | | | | | Nb0.5 | Mo1.8-2.2 |

Max. continuous service temp. of element(°C) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 |

Resistivity at 20ºC(μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 |

Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 |

Thermal conductivity(KJ/m·h·ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- |

Coefficient of lines expansion(α×10-6/ºC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 |

Melting point approx.( ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 |

Tensile strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic |

Characteristic:

- High temperature stability: 0Cr21Al6Nb furnace wire can maintain

excellent stability in high temperature environments, with a

maximum operating temperature of 1350°C.

- Antioxidant performance: Under high temperature conditions, it

forms a dense oxide protective film, which effectively prevents

further oxidation reactions and improves service life.

- Excellent resistance characteristics: 0Cr21Al6Nb furnace wire has

moderate resistivity, which can provide stable resistance value to

meet different heating needs.

- Corrosion resistance: This furnace wire has good corrosion

resistance to common corrosive media and can be used for a long

time in harsh environments.

- High mechanical strength: 0Cr21Al6Nb furnace wire has high

mechanical strength and tensile properties, making it easy to

process and install.

Specific applications:

- Industrial heating equipment: used for heating elements such as

various industrial electric furnaces, hot air stoves and ovens to

provide uniform high-temperature heating effects.

- Home appliance field: used as heating elements in electric water

heaters, electric stoves and other household appliances to provide

fast and efficient heating functions.

- Heat treatment industry: Used as heating elements in metal heat

treatment equipment to ensure precise heating temperature and

treatment effects of metal materials.

- Laboratory equipment: Heating equipment, test furnaces, etc. used

in laboratories to provide reliable heating control and stability.

In general, 0Cr21Al6Nb furnace wire is a high-resistance alloy with

high temperature stability, oxidation resistance and corrosion

resistance. It is widely used in industrial heating equipment, home

appliances, heat treatment industry and laboratory equipment to

meet heating needs in different scenarios. At the same time, the

furnace wire has good mechanical strength and processing

performance, and is easy to produce and install.