Product Description:

Pure nickel strip is a high-purity, impurity-free metal strip. It

is made of pure nickel metal, machined and rolled. Pure nickel

strips typically come in uniform thickness and width and can be

customized to meet specific needs.

Pure nickel tape has excellent corrosion resistance. It is

resistant to a wide range of chemicals, including acids, alkalis

and salt solutions. This makes pure nickel strip ideal for

equipment and components in chemical processes and corrosive

environments.

Pure nickel tape also has good electrical and thermal conductivity.

Nickel is an excellent conductive metal and can effectively conduct

electricity. At the same time, it also has good thermal

conductivity and can transfer heat quickly. Therefore, pure nickel

tape is widely used in electronic components, batteries, heat

exchangers and other fields.

Corrosion resistance:

1. Surface treatment: Surface treatment of pure nickel strips is

one of the important methods to improve its corrosion resistance.

Common surface treatment methods include electroplating, hot dip

plating and chemical plating. These surface treatments can form a

protective metal or compound layer to block the contact between the

external medium and the pure nickel strip, reducing the occurrence

of corrosion.

2. Adding alloying elements: By adding some alloying elements to

pure nickel, such as chromium, molybdenum, copper, etc., the

corrosion resistance of pure nickel strips can be significantly

improved. These alloying elements can form stable oxide films or

compounds to prevent the intrusion of corrosive media.

3. Control the purity of components: The purity of components of

pure nickel strips also affects its corrosion resistance. By

controlling impurity levels in raw materials and production

processes, the potential for corrosion can be reduced.

4. Use protective coating: Coating pure nickel strip with a

corrosion-resistant protective coating can effectively prevent

corrosion from corrosive media. Commonly used protective coatings

include organic coatings, inorganic coatings and ceramic coatings.

5. Controlling process conditions: During the processing and use of

pure nickel strips, controlling process conditions can also affect

its corrosion resistance. For example, parameters such as

processing temperature, cooling rate and stress are controlled to

reduce internal stress and the possibility of grain boundary

corrosion.

Influencing factors:

1. Temperature: Temperature is one of the important factors

affecting the corrosion resistance of pure nickel strips. In high

temperature environments, pure nickel strips may suffer from

complex corrosion forms such as oxidation, sulfidation, and

nitration. High temperature may also accelerate the erosion rate of

pure nickel strips by corrosive media. Therefore, the corrosion

resistance of pure nickel strips may decrease in high temperature

environments.

2. Humidity: Humidity is another factor that affects the corrosion

resistance of pure nickel strips. In a high-humidity environment,

pure nickel strips are easily in contact with moisture, creating

conditions for electrochemical corrosion. Oxygen, chlorine and

other substances in moisture can accelerate the corrosion rate of

pure nickel strips. Therefore, high humidity environments may have

a negative impact on the corrosion resistance of pure nickel

strips.

3. Corrosive media: Different corrosive media have different

effects on the corrosion performance of pure nickel strips. For

example, corrosive media such as strong acid, strong alkali, and

salt water may cause serious corrosion to pure nickel strips.

Factors such as the composition, concentration and temperature of

specific corrosive media will all affect the corrosion resistance

of pure nickel strips.

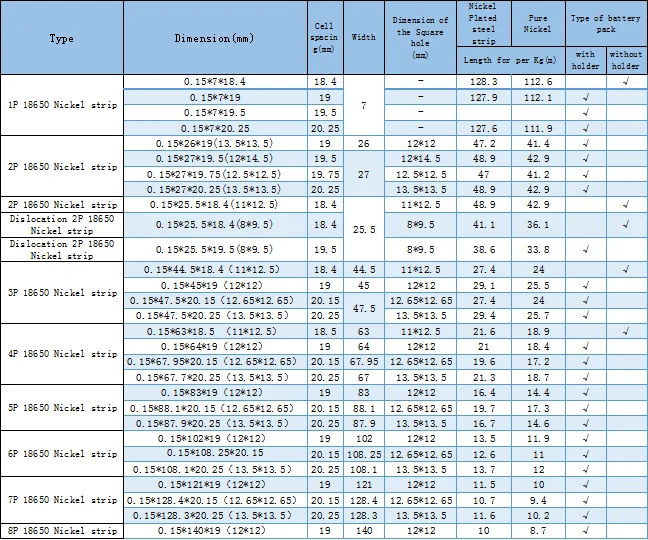

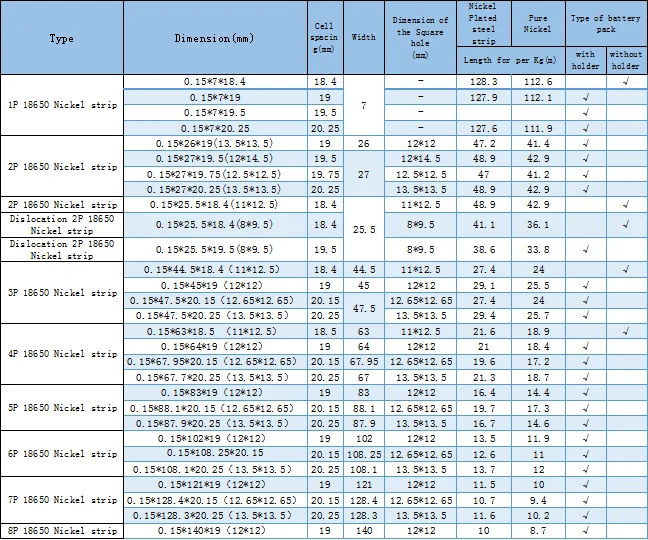

Technical Parameters:

| Attribute | Value |

|---|

| Application | Chemical Industry, Battery Assembly |

| Conductor | Pure Nickel Connector |

| Melting Point(℃) | 1435-1446 ℃ |

| Ultimate Strength (≥ MPa) | 462 |

| Power Or Not | Not |

| Type | Pure Nickel Strip |

| Material Purity | >99.9% |

| Purity | 99.5%Min/ 99.9%Min(customized) |

| Elongation (≥ %) | 45 |

| Resistance (μΩ.m) | 1.5 |

| Keyword | Description |

|---|

| Nickel Strip Price | The cost of purchasing nickel strips for various applications. |

| Fused Nickel Strip | A type of nickel strip that has been fused or welded together for

added strength and durability. |

| Pure Nickel Strip Price | The cost of purchasing pure nickel strips, which are made from

99.9% pure nickel. |

contact us

email:victory@dlx-alloy.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

FAQ:

What are the common width ranges for pure nickel strip?

The width of pure nickel strips usually ranges from 0.1 mm to 300

mm.

What are the applications of pure nickel strips in the electronics

industry?

Pure nickel tape is commonly used in the electronics industry for

applications such as battery connectors, conductive springs, and

electromagnetic shielding.

What are the advantages of the anti-oxidation properties of pure

nickel belts?

Pure nickel tape has excellent oxidation resistance and can form a

dense oxide layer in high temperature environments to protect the

substrate from oxidative damage.