Introduction:

NiCr alloy wire exhibits excellent high-temperature stability due

to its high melting point, oxidation resistance, matching thermal

expansion coefficient, crystal phase stability, and ratio of nickel

and chromium.

This makes it the material of choice for many high temperature

applications such as heat treatment equipment, high temperature

heating elements and aerospace.

1. High melting point: NiCr alloy wire has a relatively high

melting point, usually between 1200°C and 1400°C, which allows it

to maintain stable structure and performance in high-temperature

environments.

2. Anti-oxidation performance: NiCr alloy wire forms a dense oxide

surface layer in a high-temperature oxidizing environment. This

oxide layer can effectively prevent the erosion of oxygen and other

oxidants and provide protection. This anti-oxidation property

allows NiCr alloy wire to be used at high temperatures for a long

time without significant oxidation and corrosion.

3. Thermal expansion coefficient matching: The thermal expansion

coefficient of NiCr alloy wire matches that of many common

structural materials (such as steel). This means that under high

temperature conditions, the difference in thermal expansion between

the NiCr alloy wire and the surrounding materials is smaller,

reducing the accumulation of thermal stress and improving the

durability and life of the material.

4. Crystalline phase stability: The crystalline phase in NiCr alloy

has high thermal stability, that is, it is not prone to phase

change or precipitation at high temperatures. This ensures the

structural stability and performance consistency of NiCr alloy wire

under high temperature conditions.

5. The ratio of nickel and chromium: The ratio of nickel and

chromium in NiCr alloy wire plays an important role in its high

temperature stability. Generally speaking, high nickel content

improves the high-temperature stability and oxidation resistance of

the alloy, while high chromium content provides better corrosion

resistance.

Technical Parameters:

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 |

| Composición | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 |

| Fe | - | ≤1.0 | ≤1.0 | Rest | Rest | Rest |

| Temperatura máxima℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 |

| Punto de fusion ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 |

| Densidad g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 |

| Resistividad μΩ·m,20℃ | 0.76±0.05 | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 |

| Alargamiento a la ruptura | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 |

| Calor especifico J/g.℃ | - | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 |

| Conductividad térmica KJ/m.h℃ | - | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 |

| Coeficiente de expansión de líneas a×10-6/(20~1000℃) | - | 18 | 17 | 17 | 19 | 19 |

| Estructura micrográfica | - | Austenite | Austenite | Austenite | Austenite | Austenite |

| Propiedades magnéticas | - | Nonmagnetic | Nonmagnetic | Nonmagnetic | Weak magnetic | Weak magnetic |

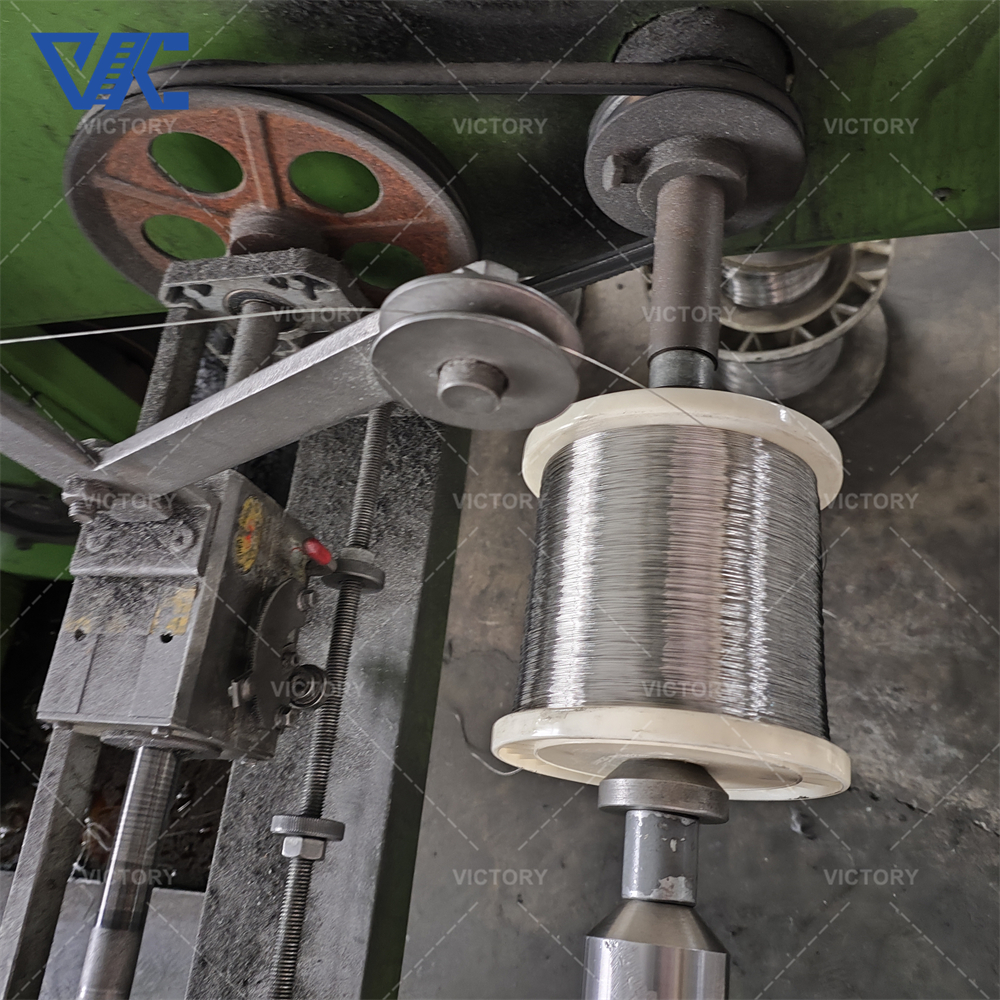

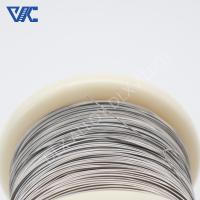

| Form | Specification |

| Wire | Diameter=0.025mm~8mm |

| Flat wire | Width=0.40~6.0mm | Thick=0.03~0.50mm |

| Strip | width=8~250mm | Thick=0.05~3.0mm |

| Bar | Diameter=8~100mm | Long=50~1000 |

Service:

Safety is our utmost priority when it comes to our NiCr alloy

heaters. We have implemented multiple safety measures, including

overload protection and overheating protection, to ensure the safe

and reliable operation of our heaters. You can have peace of mind

knowing that our products prioritize your safety and provide a

secure heating solution.

contact us

email:victory@dlx-alloy.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

Size dimension range:

Wire: 0.01-10mm

Ribbons: 0.05*0.2-2.0*6.0mm

Strip: 0.05*5.0-5.0*250mm

NiCr series: Cr20Ni80, Cr30Ni70, Cr15Ni60, Cr20Ni35, Cr20Ni30

Packing and Shipping:

Sturdy cardboard boxes are used for packaging NiCr Alloy.

Each box has dimensions of approximately 26 cm (length) x 26 cm

(width) x 30 cm (height).

The shipping method for NiCr Alloy depends on the customer's

requirements.

FAQ :

What are the typical mechanical properties of NiCr Alloy?

The mechanical properties of NiCr Alloy can vary depending on the

specific composition and heat treatment. Generally, it exhibits

high strength, good ductility, and excellent creep resistance at

elevated temperatures.

What is the cost of NiCr alloy?

The cost of NiCr alloys is generally lower and more economical than

other high-temperature alloys (such as tungsten-molybdenum alloys).

This makes NiCr alloys a popular choice in many applications.

Do you provide technical support for Cr10Ni90 alloy wire?

Yes, we provide technical support for Cr10Ni90 alloy wire,

including selection suggestions, application guidance, etc.